尾矿回收机是用于磁铁矿工艺流程中的尾矿进行回收,不使矿粉流失,使有效资源得以充分利用的一种节能高效选矿设备。该设备所用材料精良,设计结构合理,操作方便经济回报率高等特点。尾矿回收机不公可以有效的遏制污染行为,而且能够大幅度降低生产成本,大幅度的提高生产效率,具有低投入,高产出的特点。

Tailings recycling machines are used in the process of magnetite tailings recovery,not to make the slag erosion,make effective resource can be fully utilized by a highly efficient energy-saving beneficiation equipment.The device can use sophisticated materials,design a rational structure,convenient operation and high economic returns.Tailings recovery machine not only can effectively curb pollution behavior,but also can greatly reduce the production cost,greatly improves theproduction efficiency,with low input,high-yield characteristics.

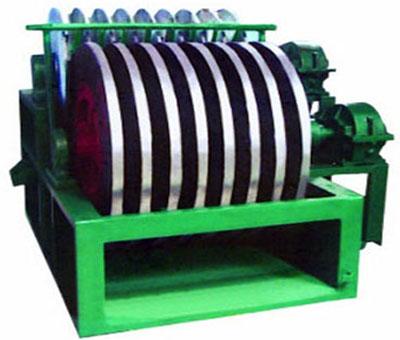

盘式尾矿回收机的结构

盘式尾矿回收机是由主机、卸矿装置、集矿槽、溜槽及机架五大部分组成。其工作原理是主机磁盘装在溜槽中,矿浆从溜槽的一端流入,并通过磁盘与磁盘的缝隙,矿浆中磁性矿物被吸附在磁盘表面,剩下非磁性矿物的矿浆从溜槽另一端流出。主机磙盘转动,吸附在磁盘表面磁性矿物被带出矿浆液面,当进入卸矿区内,由插入磁盘缝隙之间并转动的卸矿装置将磁置表面吸附的磁性矿物抛入集矿槽中,由集矿槽收集输出。

Tailings recovery disc is composed of a host,ore unloading device,set mine shafts,chute and frame five major components.Its working principle is the host disk installed in the chute,the pulp from the chute at one end into,and through the disk and disk gap,pulp magnetic minerals are adsorbed on the surface of the disk,the remaining non-magnetic minerals in the pulp from the other end of the outflow chute.Host roller tray rotation,magnetic mineral absorption in the disk surface was taken out of pulp level,when the discharge into the mining area,by the insertion of the disk gap between the rotating device unloading ore magnetic the surface adsorption of magnetic mineral cast into the collection trough,set by the mine shafts to collect the output.

盘式尾矿回收机的优点:

1. 磁场布置:磁盘磁极间距小,磁盘与磁盘之间无零磁区。

2. 卸矿:卸矿为非接触型强制卸矿,磁盘表面留有一层粉保护层,磁盘表面无磨损,整机寿命是常规型的8-10倍,使回收的磁性矿物品位提高。

3. 处理量大:该机是针对尾矿再选专门设计的,其结构具有处理大流量低品位尾矿的特点,是现有筒式磁机的处理量的几倍甚至十几倍。

4. 回收率高:所有通过磁盘之间的特料均受到磁场的作用,磙性矿物得到充分回收,回收率高。

5. 节水:由于采用独特场布置,磁性矿物含有大量水分,被卸下的矿物呈现流动状态,基本可以不加水或少量的补充水。

6. 节电:一台尾矿回收机处理量是其它设备单台处理量的几倍甚至十几倍,装机容量只有几千瓦,节电有效。

7. 安装方便:盘式尾矿回收机具有处理量大,占地小,进出料位差小,在有尾溜槽的地方基本上都可以安装。

8. 经济效益高:设备投资小,产出效益高,年产出效益一般是设备投资的几倍甚至十几倍。

Tailings recovery disc machine advantages:1.the magnetic field arrangement:disk pole spacing,,leaving the disk surface with a layer of powder coating,the surface of the disk has no abrasion,the whole life is a conventional type8-10 times,,the structure of processing of large flow and low grade tailings characteristics,,roller of minerals are fully recovered,,magnetic minerals contain large amounts of water,to be unloaded the mineral present flow state,,installed capacity of only a few kilowatts,,covers an area of small,feeding head small,,high output benefits,production efficieccy is generally the equipment investment investment is severalfold even ten times.

|

规格型号

Certification and type

|

工作面积

Working area(㎡)

|

功率

Power(kw)

|

磁极组数(片)

Group of pole(t)

|

表面场强

Magnetic strength of field appearance(MT)

|

处理量

Capacity(t/h)

|

|

800×4

|

8

|

2.2

|

4

|

170-180

|

100

|

|

800×6

|

10

|

3

|

6

|

150

|

|

800×8

|

12

|

3

|

8

|

200

|

|

800×10

|

15

|

4

|

10

|

240

|

|

800×12

|

18

|

4

|

12

|

260

|

|

1000×8

|

15

|

4

|

8

|

240

|

|

1200×8

|

18

|

4

|

8

|

260

|

|

1500×8

|

20

|

5.5

|

8

|

280

|

:2242538890 2233515786 280327213 技术:

:2242538890 2233515786 280327213 技术: :497398702

:497398702  MSN:

MSN:

在线客服

在线客服

点击查看大图

点击查看大图